Spark plasma sintering of boron carbide: A revolutionary "black technology" breakthrough in traditional sintering.

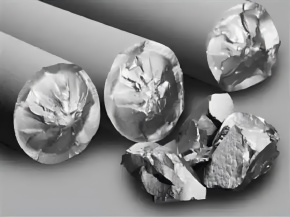

In the field of materials science, boron carbide (B4C), known as "black diamond" due to its high hardness, low density, wear resistance, and neutron absorption capacity, is widely used in high-end fields such as bulletproof armor, nuclear industry, and aerospace. However, traditional sintering processes (such as pressureless sintering and hot pressing sintering) face challenges such as high sintering temperatures, long sintering times, and easy grain coarsening, limiting further improvements in boron carbide performance. In recent years, spark plasma sintering (SPS) technology, with its low temperature, rapid speed, and high efficiency, has become a hot research area for boron carbide, reshaping the application boundaries of this superhard material.

I. SPS Technology: A Revolutionary New Paradigm for Sintering

SPS technology achieves rapid densification of boron carbide through the synergistic effect of pulsed current, mechanical pressure, and thermal field. Its core principle lies in:

Plasma activation: Pulsed current generates instantaneous high-temperature plasma in the interparticle gaps, removing surface oxides and promoting atomic diffusion.

Joule heating and temperature gradient: The electric current generates Joule heating through the graphite mold, and the temperature rises rapidly (up to 600℃/min), forming a temperature gradient that accelerates densification and inhibits grain growth.

Electric Field Assisted Diffusion: The electric field lowers the sintering activation energy, enabling boron carbide to achieve high density (>95%) at 1700-2100℃, which is 300-500℃ lower than the traditional process.

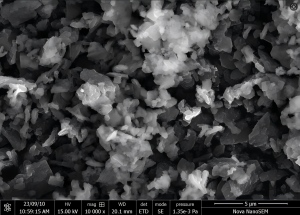

Compared with traditional sintering, boron carbide prepared by SPS has finer grains (nano to micron scale) and superior mechanical properties. For example, at 1600℃ and 300MPa high pressure, the fracture toughness of boron carbide prepared by SPS is increased to 5.56MPa・m¹/², and the dynamic toughness is significantly enhanced.

II. Technological Breakthrough: The Key Leap from Laboratory to Industrialization

1. Parameter Optimization and Microstructure Control

Temperature and Pressure Synergy: Research has found that at low temperatures (1700-2000℃), particle boundary sliding primarily leads to densification, while at high temperatures (>2000℃), dislocation climb is dominant. By precisely controlling the heating rate and pressure, grain size can be accurately controlled from 4μm to the nanometer scale.

Innovative Applications of Sintering Aids: Adding additives such as Al, SiC, and graphene can further optimize performance. For example, B4C/SiC/Al multiphase ceramics with 1.5% graphene (GPLs) show a 25.6% increase in fracture toughness and a 99% increase in flexural strength.

2. One-step fabrication of functionally graded materials

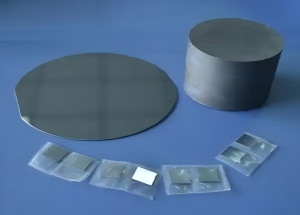

The Napo Materials team has achieved, for the first time, one-step sintering of B4C/Al functionally graded materials using SPS technology. This material achieves a gradient transition from pure B4C (hardness 32 GPa) to pure Al (hardness 1 GPa), successfully solving the problems of large melting point differences and easy formation of impurity phases in traditional processes, providing new ideas for bulletproof armor and high thermal conductivity composite materials.

3. Performance Breakthrough in Extreme Environments

In the nuclear industry, SPS-prepared B4C neutron absorbers achieve a purity of 99.9%, exhibit excellent radiation resistance, and have waste disposal costs that are only one-fifth of those of traditional cadmium-based materials. In the aerospace industry, boron carbide/aluminum composite materials reduce the weight of turbofan engine leading-edge protection plates by 40% and improve fuel efficiency by 2.3%.

III. Industry Prospects: A New Blue Ocean in a Trillion-Dollar Market

1. Applications are flourishing across all fields.

Defense and Military Industry: The U.S. military's Osprey transport aircraft uses B4C composite armor, which reduces weight by 40% and provides protection superior to traditional steel armor.

Semiconductors and Electronics: Boron carbide wafer stage flatness error < 1μm, meeting the ultra-high precision requirements of EUV lithography machines. Zhihe New Materials' low-temperature sintering technology reduces the B4C sintering temperature to 1950℃, driving its application in the semiconductor polishing pad field.

New Energy and Environmental Protection: Boron carbide nozzles extend the lifespan of high-pressure sandblasting equipment from 3 months to 2 years, reducing maintenance costs by 80%. Their application in nuclear energy, solar cells, and other fields is also rapidly expanding.

2. Market Size and Policy Dividends

The global boron carbide market is projected to grow from $180 million in 2025 to $320 million in 2030, representing a CAGR of 9.5%. As the world's largest producer, China is seizing the industry's leading position through policy support and technological breakthroughs.

Spark plasma sintering (SPCS) technology is leading boron carbide materials from the laboratory to industrialization. Its superior performance in hardness, thermal stability, and neutron absorption provides disruptive solutions for defense, energy, and electronics. With technological advancements and policy support, boron carbide, this "black diamond," will undoubtedly shine in even more applications, becoming one of the key materials driving human technological progress.